Boiled Sausages

Quality is our passion!

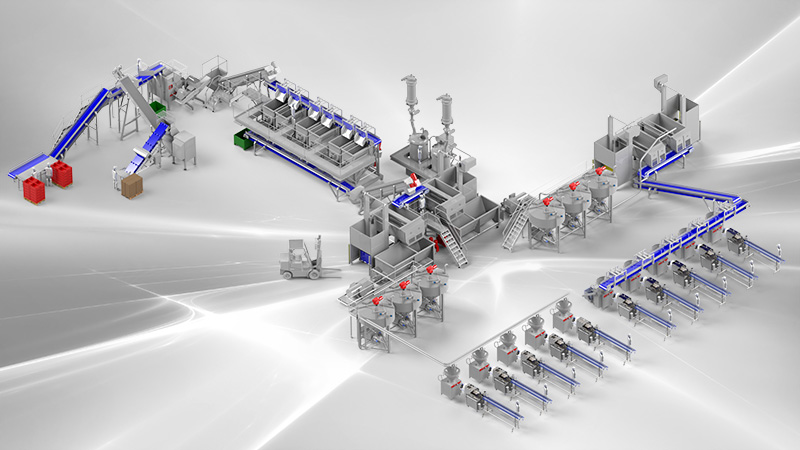

Sample process solution

Conveyors

Read more!

Breaker 650/1000/1300

Read more!

Automatic Grinder

Read more!

Storage Bins

Read more!

Process Automat B-Series

Read more!

Lifting Device

Read more!

Mixer

Read more!

Mixer

Read more!

Feed Hopper

Read more!

Emulsifier

Read more!

Storage Silos

Read more!

Sausage Hanging Line

Read more!

Boiled Sausages

Quality is our passion!

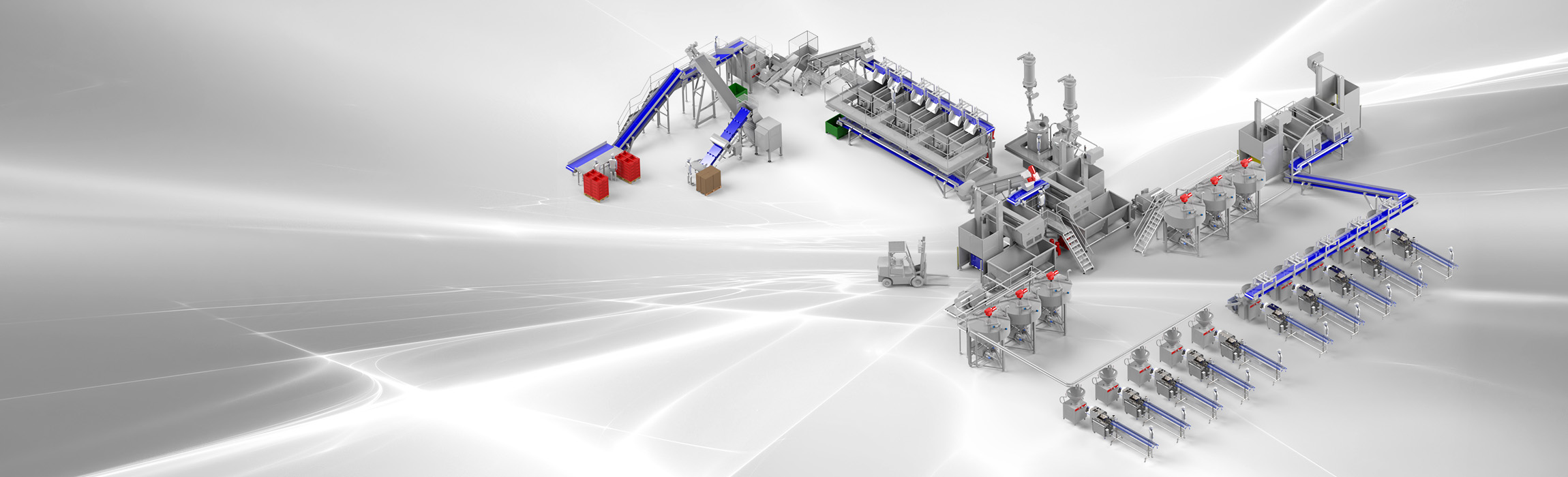

Sample process solution

Conveyors

Read more!

Breaker 650/1000/1300

Read more!

Automatic Grinder

Read more!

Storage Bins

Read more!

Process Automat B-Series

Read more!

Lifting Device

Read more!

Mixer

Read more!

Feed hopper

Read more!

Emulsifier

Read more!

Storage Silos

Read more!

Mixer

Read more!

Sausage Hanging Line

Read more!

Highly flexible production lines for meat processing

A variety of product flows can be implemented to produce high-quality sausage meat or coarse-grained products on the same system. This is due to the comprehensive KARL SCHNELL machine range which covers all production steps from meat preparation to filling.

The production recipes are composed, starting with a modern and future-oriented recipe control with a possible connection to superior planning systems.

Frozen meat breakers and grinders, being able to gently process both frozen and fresh uncooked goods, are used to make a pre-standardization before the mixing process.

In addition, an online NIR system is used to analyze the meat standard before the mixing. And if necessary corrective material can be added to achieve the required standard while feeding the mixer. This saves valuable time during the mixing operation.

In the sophisticated KS Mixers, equipped with the most diverse mixing tools and numerous options, the recipe is completed – homogenous and with consistent quality.

Spices and other additions can be added automatically over dry products metering systems or KS Process Automats in which liquid suspensions are homogenized. This type of admixture has the great advantage that the meat mixture is better moistened by the slurry and is better taken up. Furthermore the blending of the additives takes less time.

After the mixing process all possibilities of the further processing are open.

Fine sausage meat recipes are e.g. drained into a feed hopper and then gently conveyed to an emulsifier.

For special products KARL SCHNELL offers a wide variety of process automats.

Another possibility consists in the further processing of recipes that are not emulsified. They can be filled directly for example.

With the KS Emulsifiers a machine type is available which has set the standard in this sector and has a very good reputation in the food industry. Thanks to the numerous cutting set and equipment variants all demands of the market can be realized.

Storage Bins are a further important element in a fine sausage meat line solution between emulsifier and the following filling machines. They ensure a continuous product flow. Fine sausage meat silos are, adapted to the following product transport, available with pump or slider discharge.

For the automated fine sausage meat transport up to the fillers KS offers solutions with pumps or conveyor belts that gently handle the product.

The latest generation of conveyor belts is characterized by a hygiene-optimized construction as well as a huge variability, such as slider feeding of the filling systems.

To round off the automated line KS offers high-performance filling machines with innovative control technology and user friendly operating convenience. Their proven conveying system is the guarantee for the continuous working process.

A wide variety of attachments complete the program.

To clean a modern flexible line-solution economically and to meet the hygiene standards of today, KS supplies also the respective cleaning ball and CIP systems. Pipelines and machines are incorporated in cleaning circuits.

Above and beyond a complete line-structure is a state-of-the-art control and sensor technology which makes such a solution possible. Via touch panels with visualization of the system parts the operator always maintains the survey of all production processes. The communication with superior administrative systems rounds out the system control.