Soups & Sauces, Spreads, Paté

The smart concept for new product ideas!

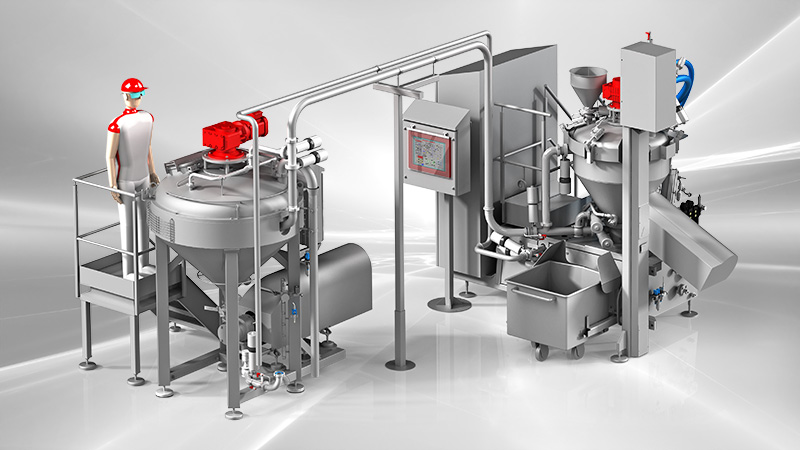

Sample process solution

Process Automat FV-Series

Read more!

Lifting Device

Read more!

Storage Silo

Read more!

Soups & Sauces,

Spreads,Paté

The smart concept for new product ideas!

Sample process solution

Lifting Device

Read more!

Process Automat FV-Series

Read more!

Storage Silo

Read more!

Higly flexible integrated solution

All recipe components are supplied via conveyors or pumps. Powders can be dosed dust free by a fully automatic powder dosing system. Even short premixing guarantees a lump free product and the dissolution of the stabilizers and other powder components – an important fact to get the maximum stabilizing effect.

If necessary, thermization takes place at temperatures up to 110 °C. The energy is transferred in form of direct steam injection under vacuum conditions into the product and / or over a steam heated double jacket.

If the recipe and the dry matter of the raw material allow a direct steam injection, this method should be preferred. It offers the best energy efficiency and the highest product protection and excludes Maillard reaction and caking.

The most important element in the process is the homogenization, done in the KS Process Automat. The homogenization force and the sheering effect are strong enough to create the desired viscosity and stability of the product.

KS Process Automates are equipped with high speed rotating pre-cutting knives. Additionally the product is passed through the in-built KS Cutting System when it is discharged. If this is not sufficient, the product can be processed through a recirculation system until the desired quality is reached.

The following buffer silo ensures a smooth and continuous production.