Groundbreaking ceremony for the new production hall at the Creglingen site

« With the groundbreaking, another strong signal is being sent for the Main-Tauber district. We have many exciting and innovative companies in the county. As district administrator, it fills me with pride that a leading family-owned company from the region has consciously decided to invest and expand in its location in the county. I assure you: the county administration firmly stands by your side in this endeavor, » stated District Administrator Christoph Schauder.

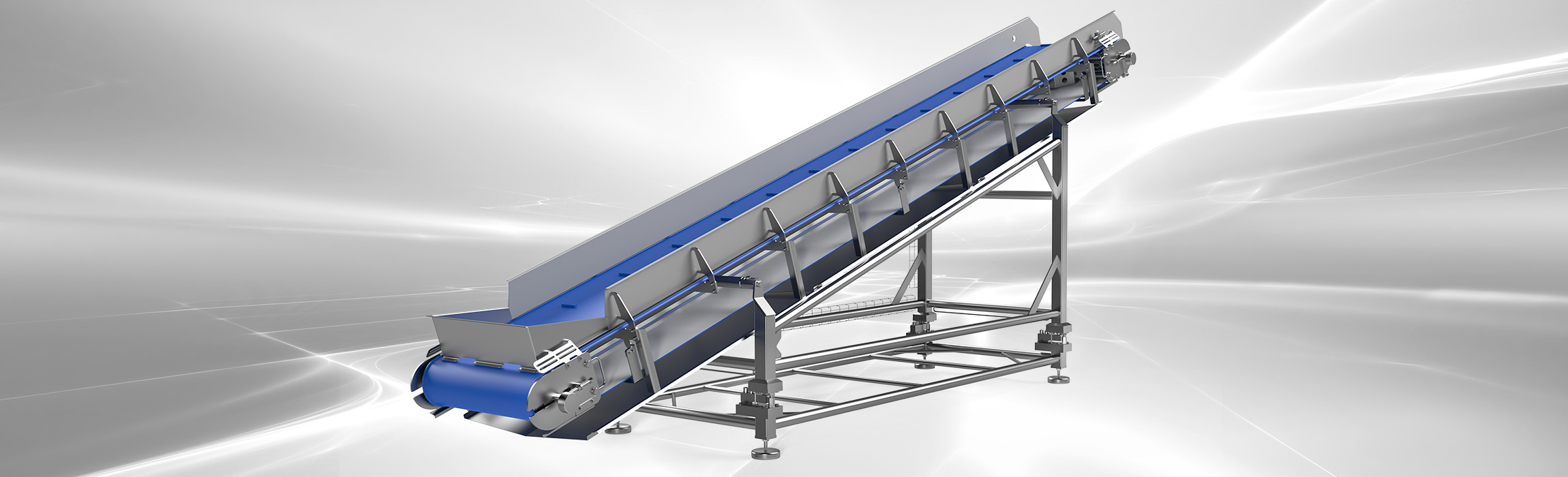

Industry leadership thanks to constant innovation readiness

As a partner to the food industry, KARL SCHNELL has been offering a wide range of products for over 75 years. Currently, the focus lies in machinery and plant construction for the industrial processing of meat products, pet food, delicatessen, and processed cheese products. « Our portfolio ranges from individual customizations to automated complete solutions. We place great emphasis on the interplay of innovation, quality, and efficiency, » said Managing Director Dr. oec. Ernst-Otto Schnell.

Construction work for the 90-meter long and 25-meter wide new building is set to commence as soon as the final building permit is obtained. Commissioning is planned for spring 2025. Upon completion, the modern hall will optimize production processes for sheet metal fabrication. « With the new building, we are continuing the consistent path at our location in Creglingen. A modern, efficient, and logistically sensible production process is the basis for successful business operations, » said Operations Manager Philipp Schnell, referring to the hall built two years prior adjacent to the current planning project.

« This investment is a positive signal for the region because in times of dwindling skilled workers, it’s attractive and modern workplaces that convince young people to pursue a career at home. Many companies offer diverse fields of work and promising career opportunities, » explained Councilor Ursula Mühleck. At the German mechanical engineering company, for instance, one could embark on apprenticeships as product designers, construction mechanics, mechanics, or electricians. « This diversity is a real asset for our region, » added Mayor Uwe Hehn.