DIAphragm

Servo technology for best product quality

DIAphragm

Servo technology for best product quality

Precise shaping with highest portioning accuracy

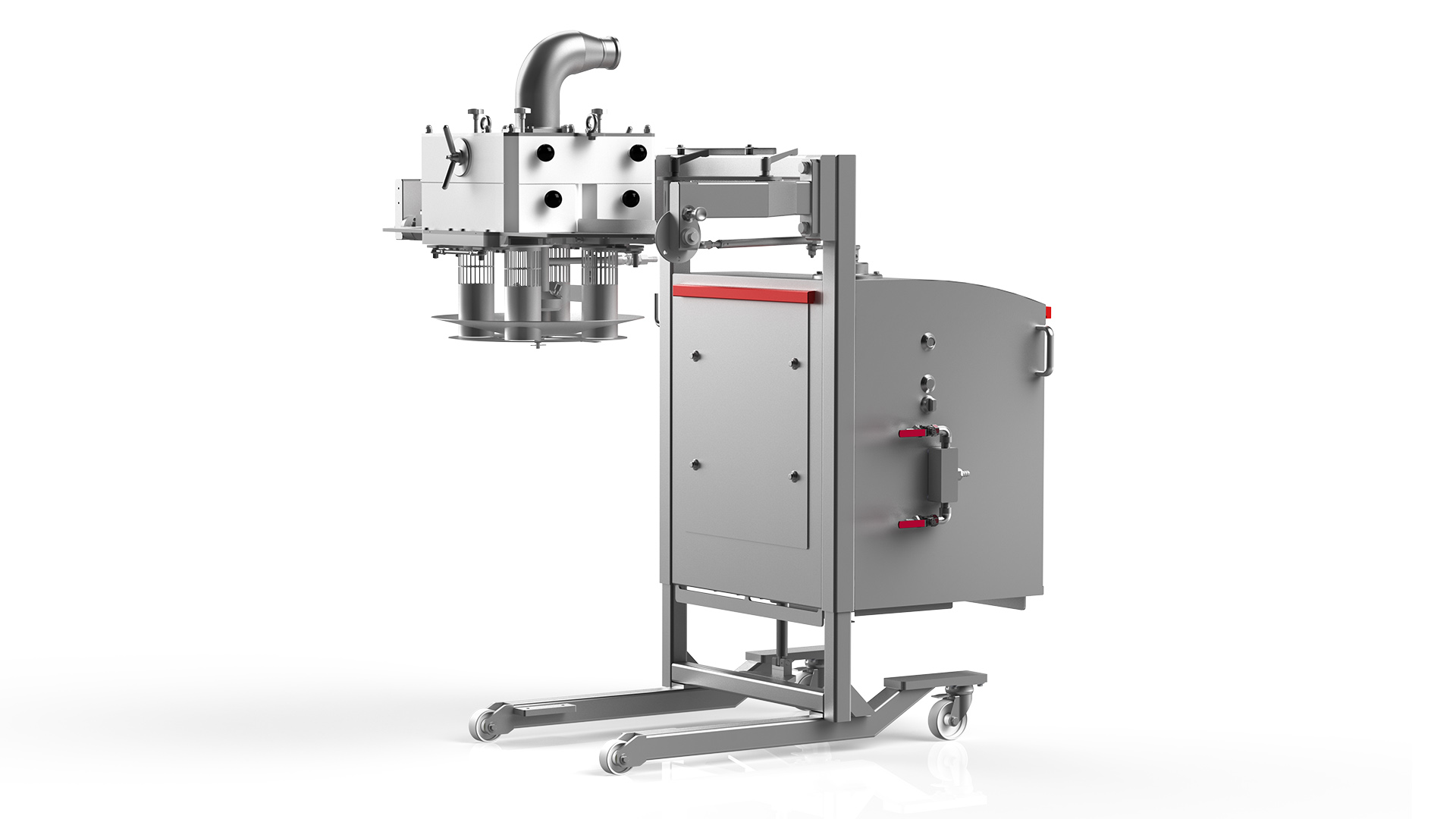

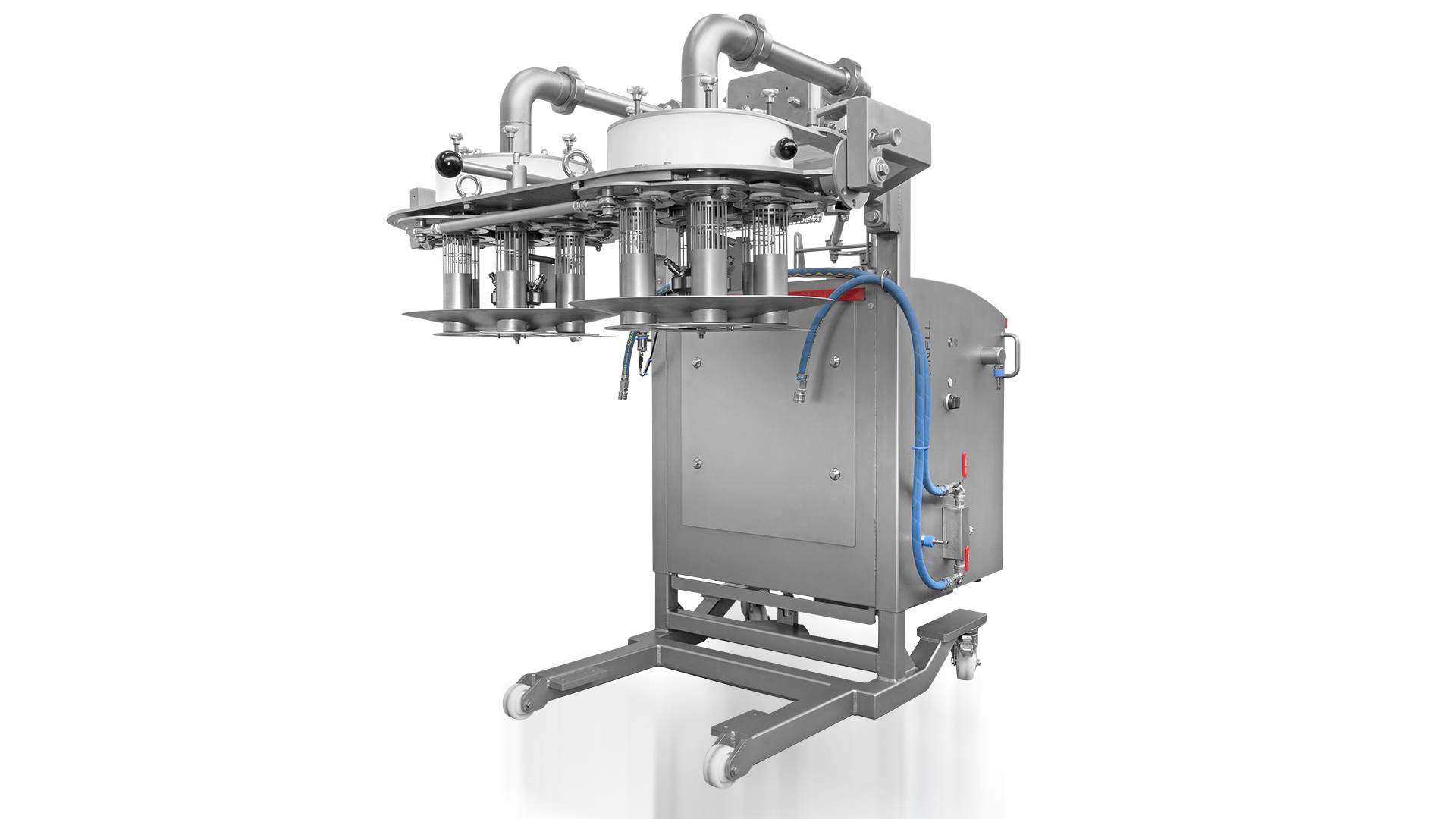

The KS Diaphragm is an attachment which can be used universally for portioning and straight filling. Shape, contoures and product diameter can be selected to 70 mm. The KS Diaphragm can be obtained in different versions with 1 to 12 portioning heads.

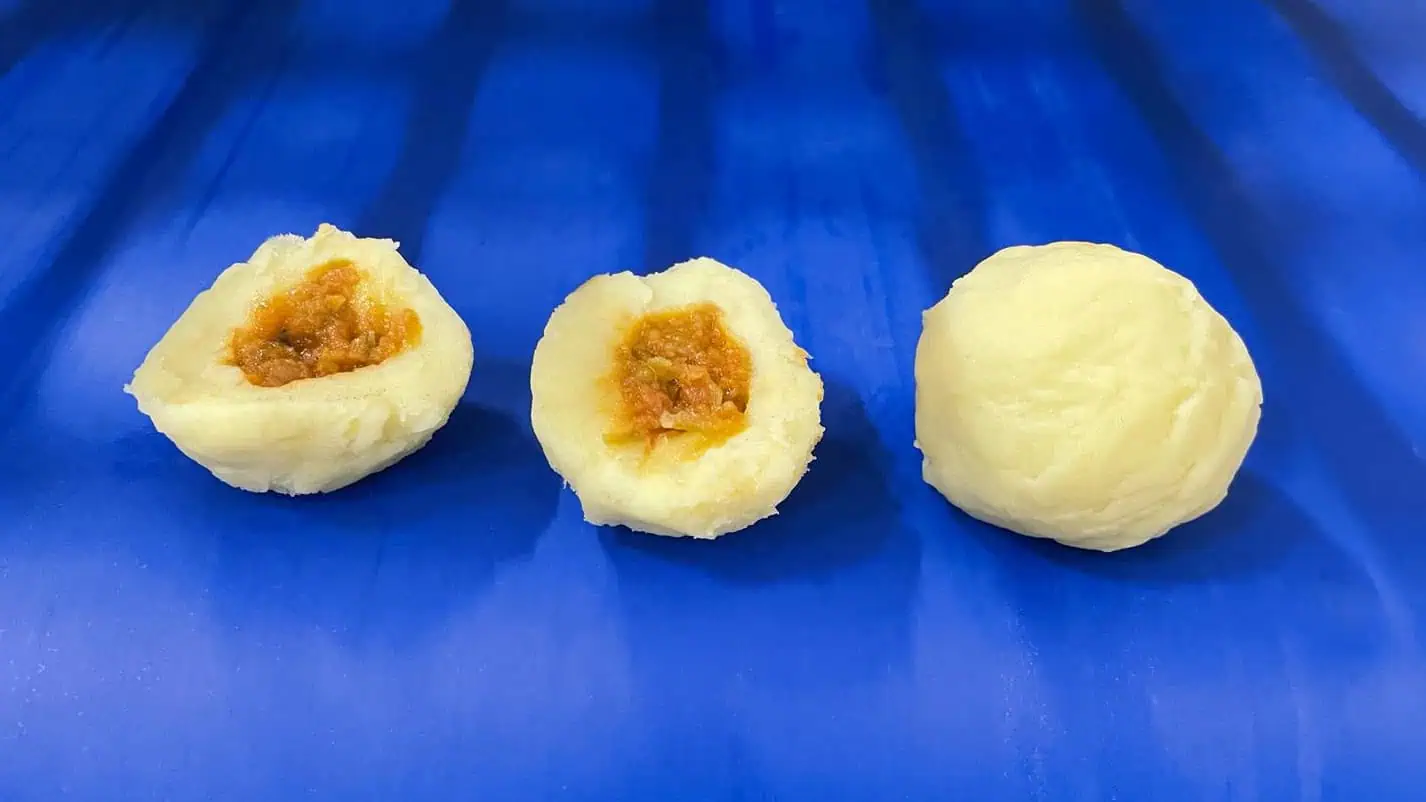

There is also the possibility of product injection – what is called coextrusion.

The high-performance KS Vacuum Filler provides an even, gentle on the product and need-based supply of the downstream portioning and forming device and thereby lays the foundation for optimum process reliability.

The KS Diaphragm is appealing due to its newly developed drive concept based on a highly dynamic servo motor. The specification of the shape and the size of the product to be processed is solely through parameter setting in the control. This is accomplished easily on the large touch screen of the filling machine. Laborious mechanical settings while producing and even at product changeover are no longer necessary. Adaptation of the production parameters can be done any time during operations.

Whether dumplings, meat- or cheeseballs, Gnocchi, croquettes or sticks – due to the manifold setting options there is a huge potentiality for new product design.

The electromotive height adjustment of the complete diaphragm unit allows customization to individual requirements (cooking bath, transportation belt).

In addition KARL SCHNELL provides with the KS Belt Conveyor a specific designed attachment for the integration into complete production lines. This ensures safe and hygienic transportation to the following processes.

The KS Diaphragm provides process reliability, quality and lasting value and thus a value enhancement for the customer.