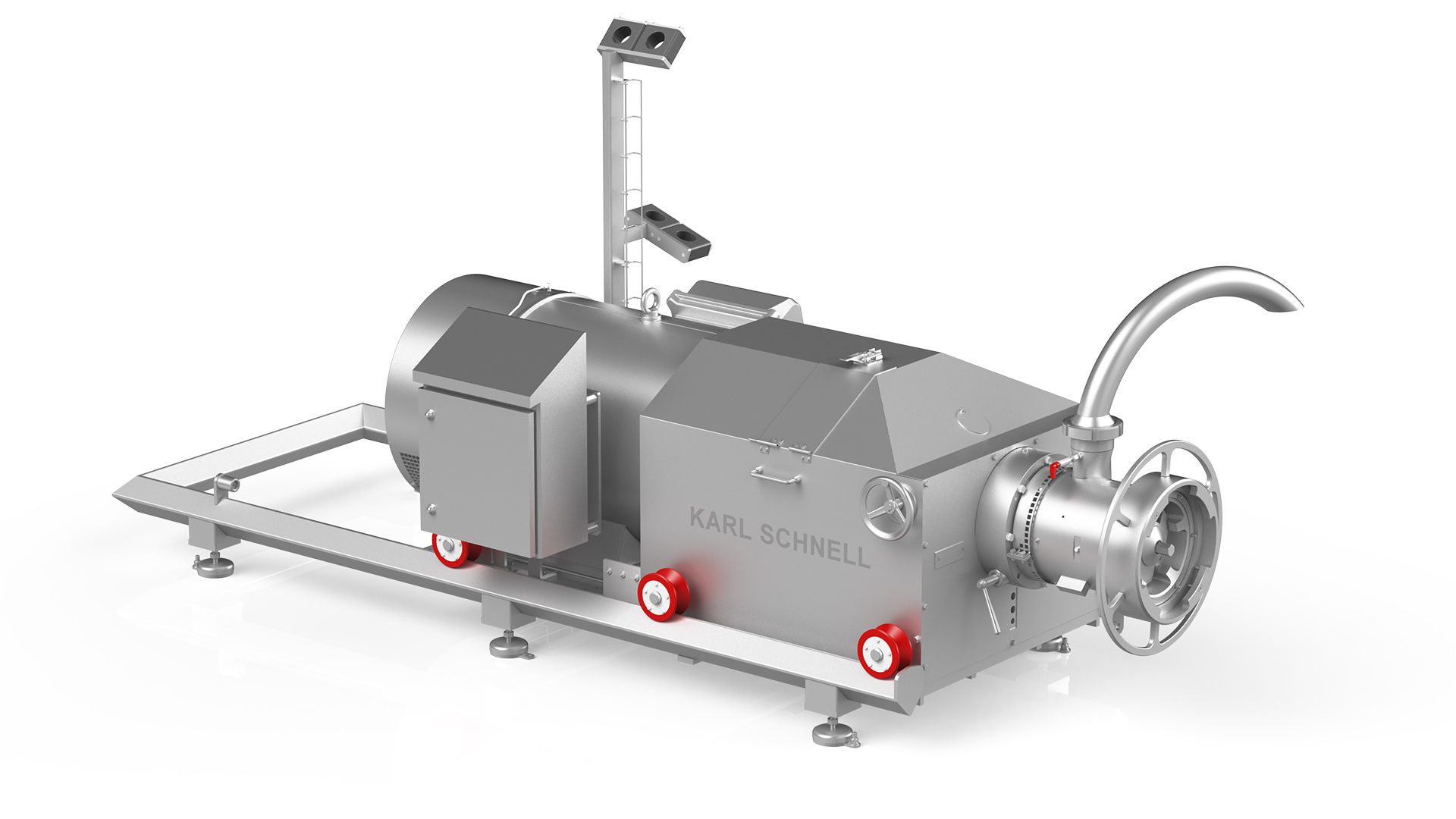

Emulsifier FL225 / FL248

The strongest emulsifier worldwide!

Emulsifier

FL225 / FL248

The strongest emulsifier worldwide!

High power for highest efficiency

The FL225 respectively the FL248 are the strongest emulsifiers from KS!

With throughput quantities of 5 000 kg/h (for processing ultra dry and cold raw materials with high solid proportion) up to 25 000 kg / h (for processing raw materials with low viscosity characteristics) they set the standard wherever is a need to handle largest quantities.

The new drive concept of KS emulsifiers with most modern servo technique is a further milestone in terms of efficient, process-optimised production. Water-cooled, high-torque engines guarantee a hygienic and low-noise operation. Highest torque accuracy and consistency improve the efficiency and reduce at the same time the wear of the cutting tools.

Above all in the pet food sector, the combination of the new drive technology with a high performance feeding system based on a torque motor is pioneering. Herewith the cutting of extremely cold and solid substances is possible.

The automatic knife readjustment – AMN, developed by KARL SCHNELL, thereby allows an accurate and automatic cutting set adjustment and readjustment. This ensures cutting accuracy with steady cutting capacity. As a result, reproducible, constant product quality and a significantly longer service life is achieved.

The control takes place via PLC directly at the emulsifier and can be easily integrated into a complete plant control at any time. Execution of the control cabinets in hygienic design is standard at KS machines and thus ensures a faultless production also in wet rooms. A user-friendly and auto-explaining user interface enables the operator to program all parameters such as temperature, knife distance and speed easily and quickly. In this way, up to 30 different programs can be stored for a wide variety of production processes.

A large number of additional equipment is available and can be combined freely with each other.

- Vacuum devices vent the product to be produced.

- Feeding systems ensure continuous product flow.

- Direct heating and cooling systems on the feed hopper enable exact temperature control. Specially developed injection nozzles enormously reduce the consumption of the cooling and heating media used.

- Separating devices remove unwanted materials and thus offer the customer a further component for a constantly high quality and safe production.