Block Cheese, IWS, SOS

Maximize your capacity utilization!

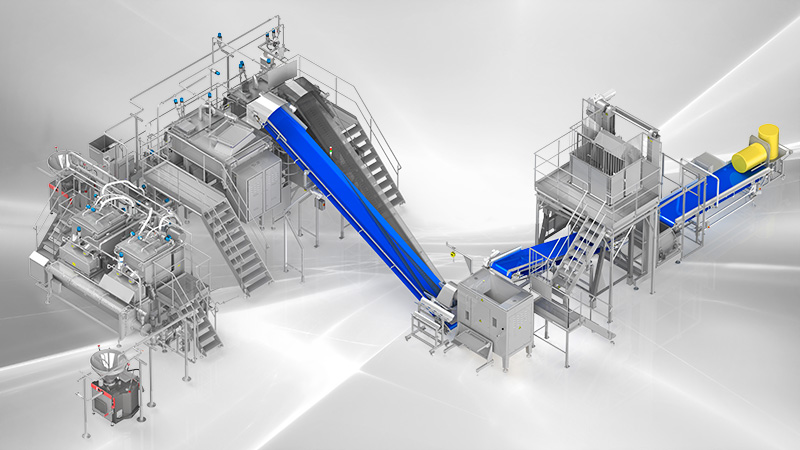

Sample process solution

Belt Conveyor

Read more!

Lifting Device

Read more!

Breaker K

Read more!

Grinder

Read more!

Mixer

Read more!

Feed Hopper

Read more!

Mixer

Read more!

Feed Hopper

Read more!

Vacuum Filler

Read more!

Block cheese, IWS, SOS

Maximize your capacity utilization!

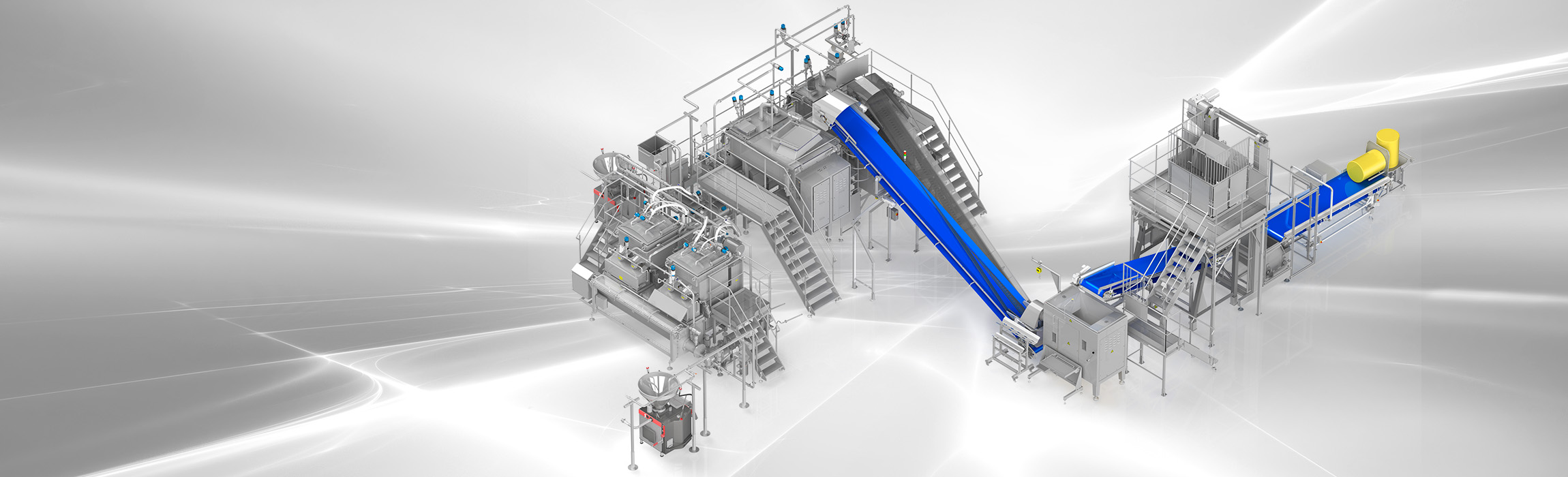

Sample process solution

Vacuum Filler

Read more!

Belt Conveyor

Read more!

Lifting Device

Read more!

Breaker K

Read more!

Grinder

Read more!

Belt Conveyor

Read more!

Mixer

Read more!

Feed Hopper

Read more!

Mixer

Read more!

Feed Hopper

Read more!

Reliable productivity by integrated system solutions

KARL SCHNELL is the ideal partner for the processing of sliceable processed cheese. Because almost all components of our process lines are supplied from a single source and thus optimally coordinated with each other. KS offers enormous production flexibility, which is due to the very high level of vertical integration in our own factories. Decades of experience in the design and development of lines, regardless of whether they are fully automatic or manually operated, are the guarantee for their outstanding performance.

We offer tailor-made solutions even for extreme requirements or in difficult building conditions.

Depending on the requirement profile, a typical processing line begins with raw material standardization. Consisting of breaker and grinder – in combination with the transport equipment, such as lifting devices, conveyor belts and screw conveyors, also from the KS range.

The next step is the recipe creation.

In mixers whose mixing tools can be optimally adapted to the product, the formulations are completed, supporting e.g. by automatic powder / water metering via KS Process Automats.

The optimum homogeneity of the product mixture with the smallest possible cycle time is top priority.

For a continuous process flow buffer tanks are recommended after the standardization mixers from which mixers with vacuum and heating equipment are subsequently fed.

KS also has solutions for special requirements, such as extremely high dry masses or special structures in the product. For example, forward-leaning mixers or emulsifier in the bypass.

Silos for intermediate storage and buffering of processed cheese and other pasty products before filling increase the efficiency of the process line.

KS high-performance Vacuum Fillers with innovative control technology and user-friendliness round out the processing line.