Baby Food & Pureed Food

Safety has priority

Sample process solution

Emulsifier

Read more!

Mixer

Read more!

Srew Conveyor

Read more!

Breaker 650/1000/1300

Read more!

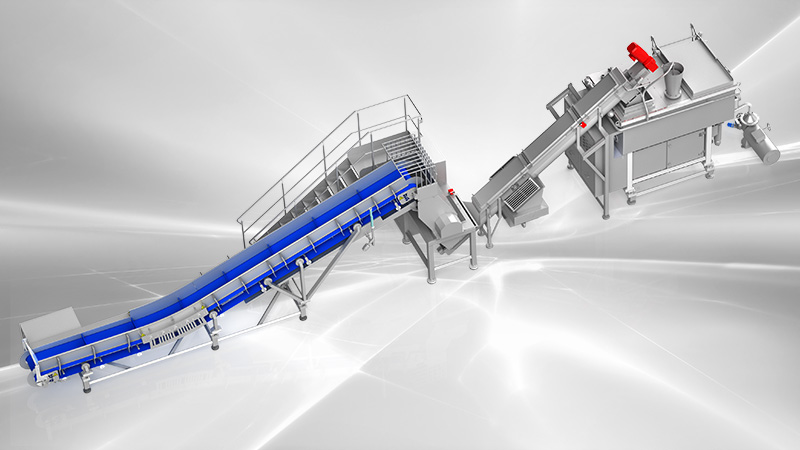

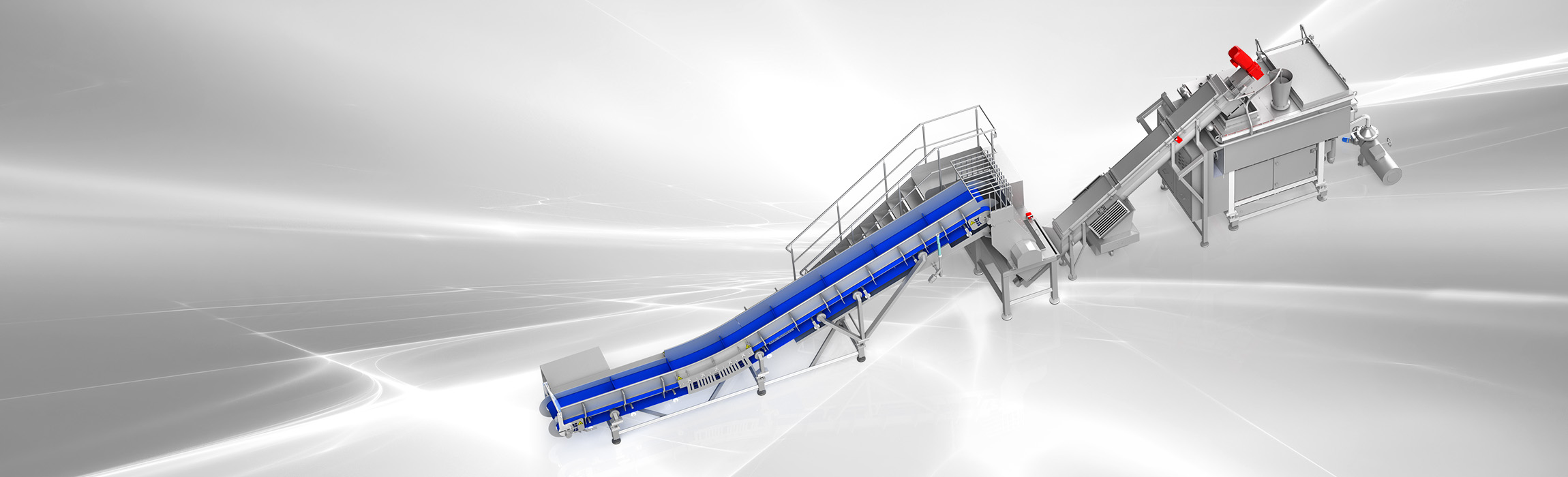

Belt Conveyor

Read more!

Baby Food & Pureed Food

Safety has priority!

Sample process solution

Emulsifier

Read more!

Mixer

Read more!

Screw Conveyor

Read more!

Breaker 650/1000/1300

Read more!

Belt Conveyor

Read more!

Tasty food in best quality

The particularly sensitive food industry places the highest demands on mechanical engineering. The focus in the international market is increasingly set on hygiene design and system stability.

In the production of special nutrition for certain groups of people such as babies, infants, seniors or people in need of care, it is particularly important to comply with very specific requirements.

- The creation of a homogeneous and always consistent end product according to a defined recipe.

- The choice of cold and/or hot processes on a production line.

- The production of a final product free of impurities and foreign bodies in exactly defined fineness.

For pureed food, we offer a range of machines and process lines that can be used to realize all the required work steps and capacities.

In the above example for a line of higher capacity this would be

- Step 1: Unpacking, weighing and forwarding the frozen raw materials (IQF)

- Step 2: Breaking the frozen starting materials

- Step 3. Mixing including heating to make a homogeneous cooked or just

heated mixed product - Step 4: Emulsifying to produce the defined product fineness

Thereafter, the product may go directly into the packaging or e.g. used as an admixture for another formular.

These process steps can also be combined in a single machine, the KS Process Automat, for lower capacity applications.