Grinder Head &

Rotation Cutter

Innovation in portioning of minced meat!

Grinder Head &

Rotation Cutter

Innovation in portioning of minced meat!

Quality is our passion!

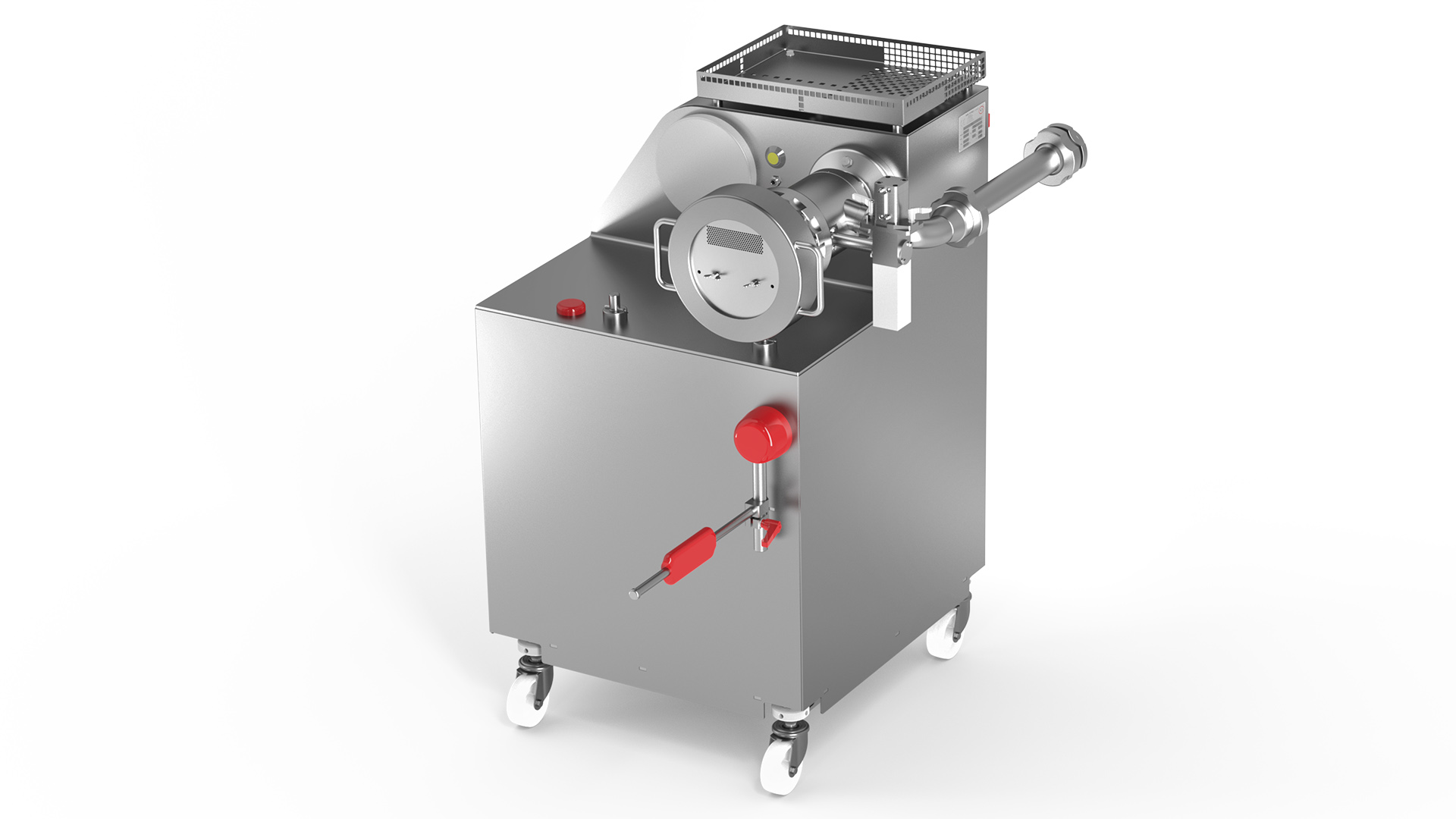

The increasing demand for minced meat products will be serviced by KARL SCHNELL with a new developed production line. The basis of this line is the high-performance industrial filler P10 SE with its product gentle pump system.

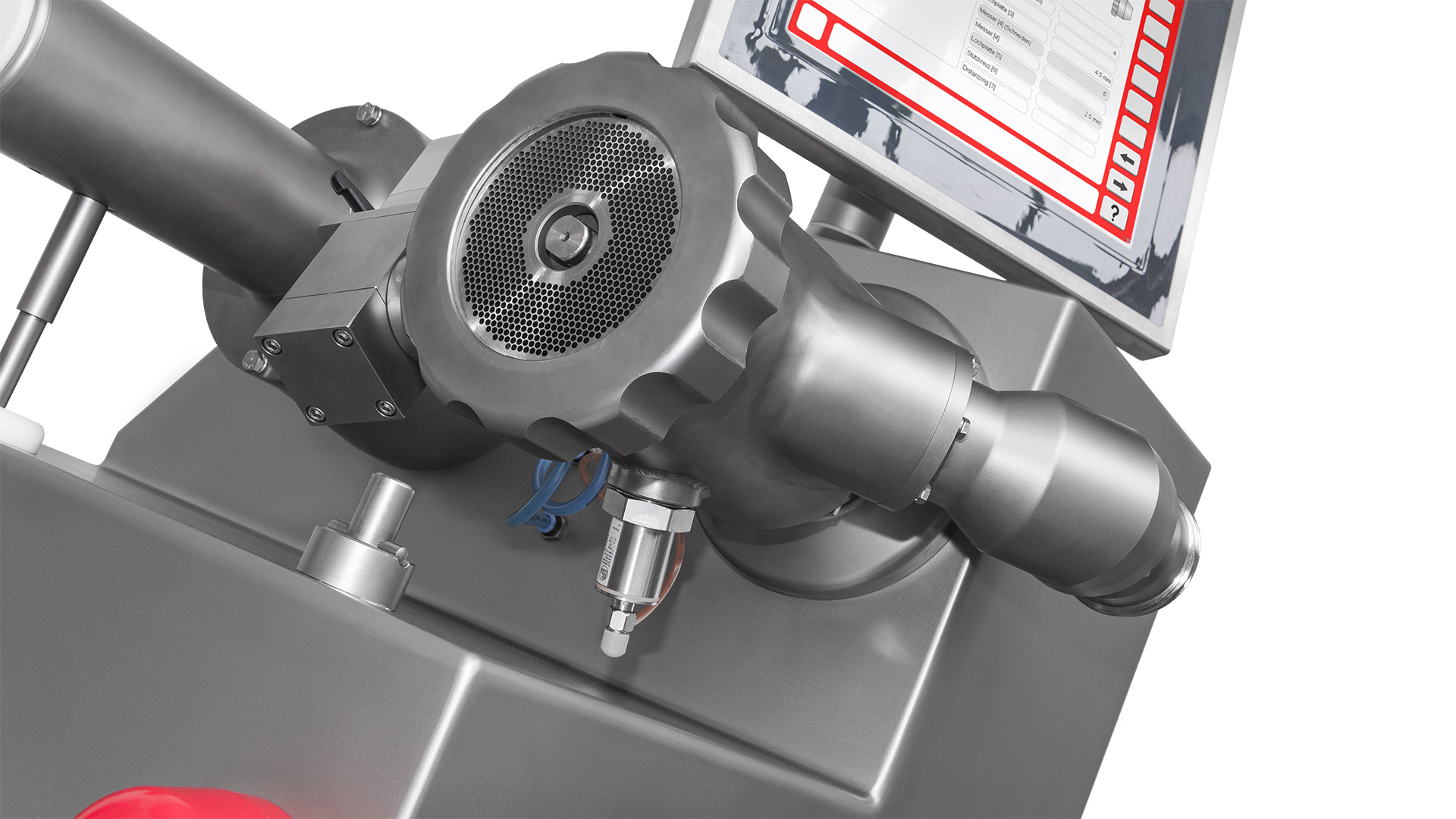

The KS Grinder Head 130 is connected subsequently. The meat is grinded with its individual adjustable cutting set to the desired grain size, prepared in structure and conveyed in a continuous flow directly onto the conveyor belt of the following rotation cutter.

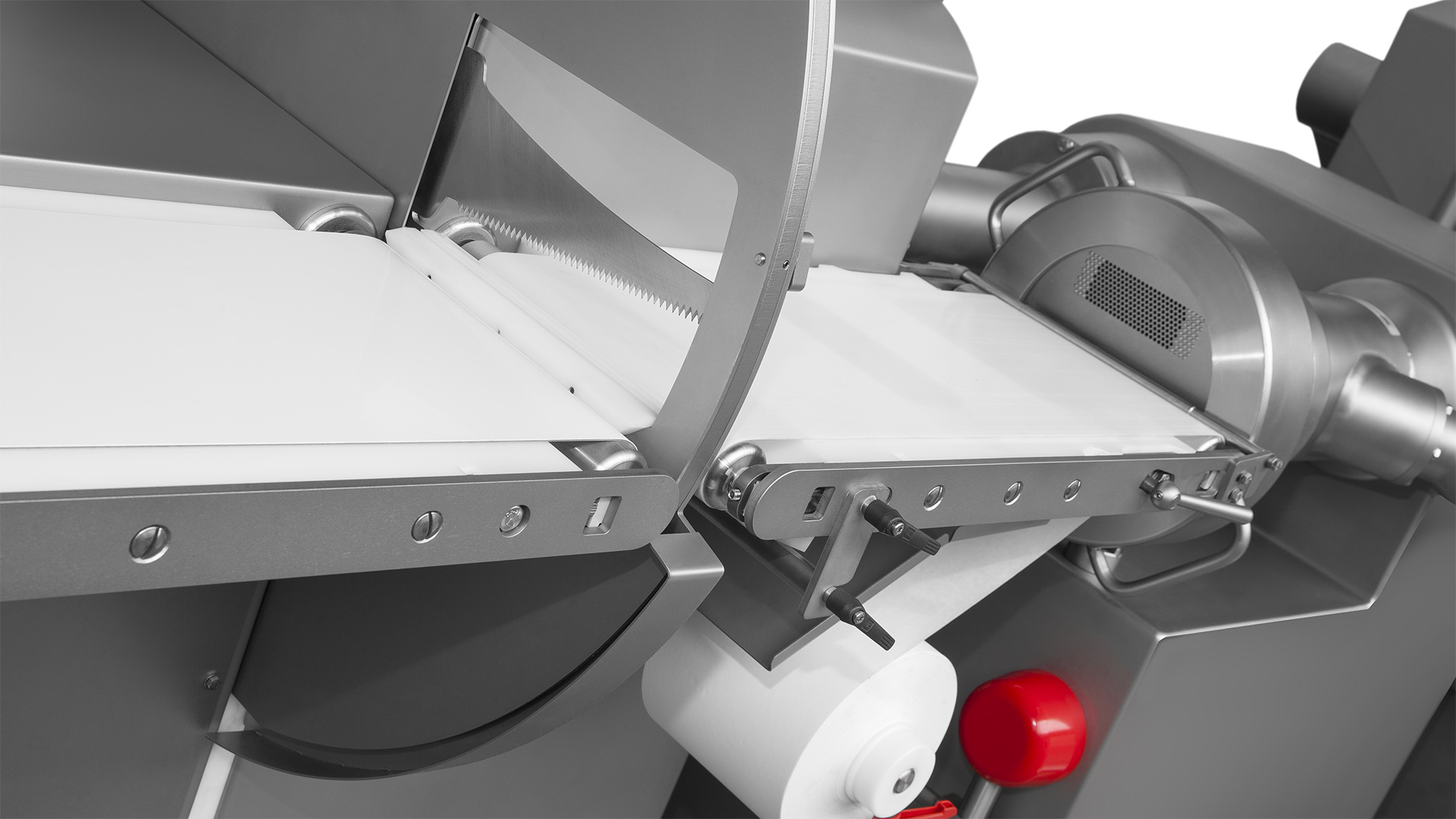

According to the principle “a chain is only as strong as its weakest link” the engineers at KS followed an extraordinary way for the actual portioning. Due to the unique cutting geometry the product is cut and separated in a continuous flow by the KS Rotation Cutter. Thereby the product will neither be decelerated nor accelerated.

The KS minced meat line can portion the product in one or more parallel strings, with individual cross section in defined sizes from 100g to 1000g.

The whole system is centrally and comfortable controlled via a 15” touch panel at the vacuum filler. The parameters of the product can be changed directly during the running production and the alterations will become immediately valid and apparent.

Of course KARL SCHNELL provides also the appropriate weighing and packaging units.