Emulsifier FL 175

Perfect fineness. The next level.

Emulsifier FL 175

Perfect fineness. The next level.

The future in emulsifying

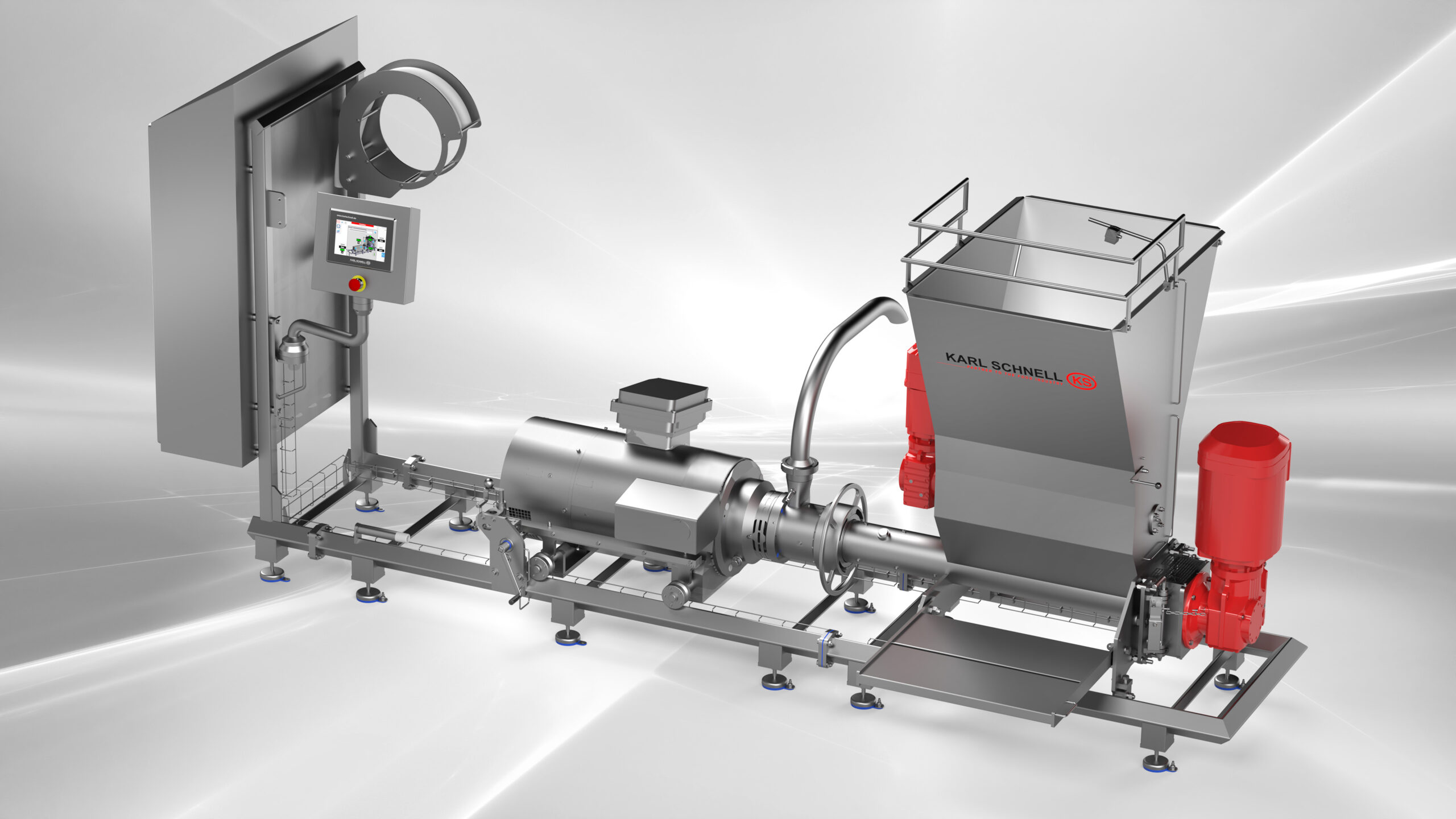

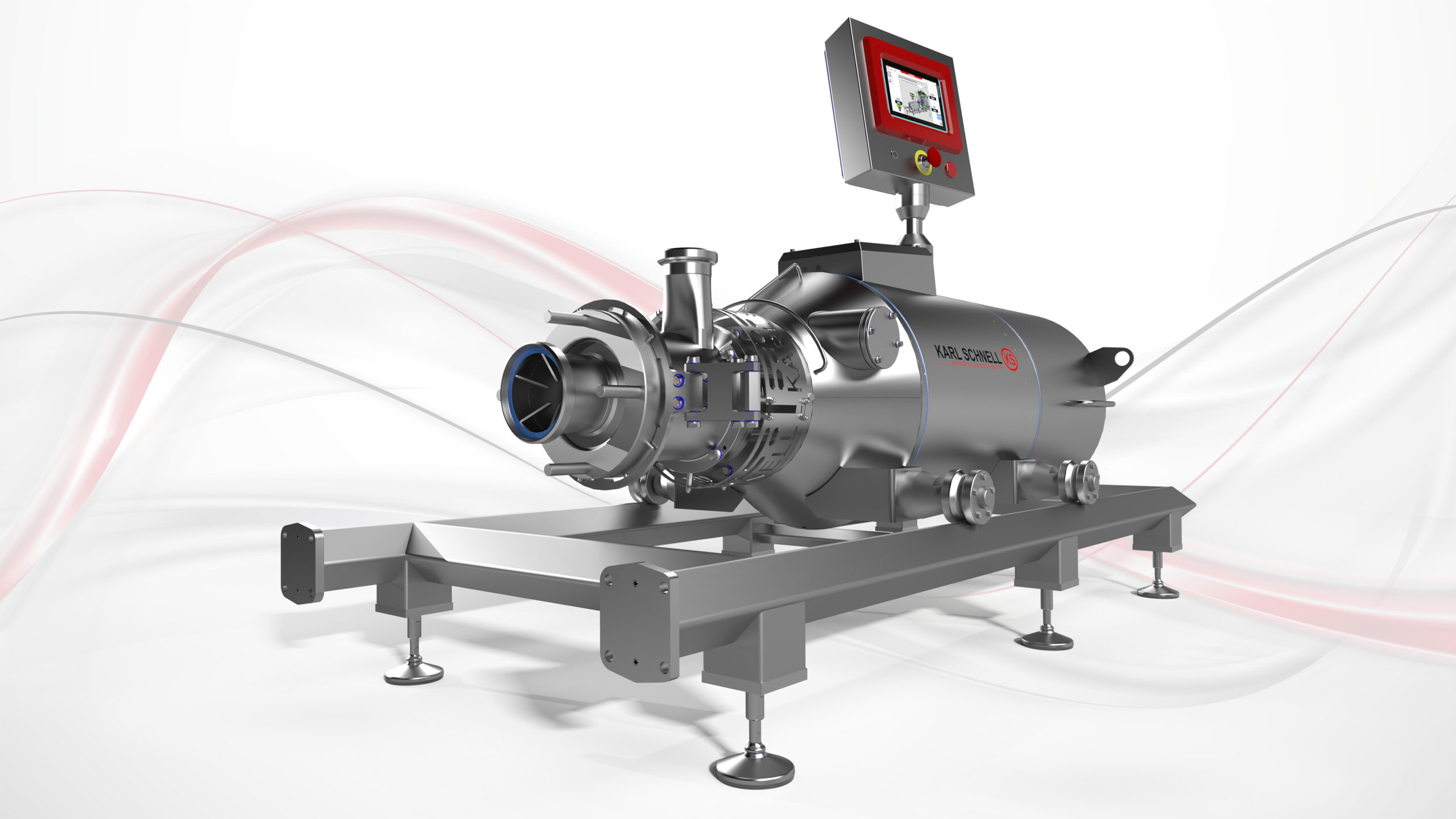

KS emulsifiers are core components of numerous innovative process lines. They can be flexibly equipped for various application-specific cutting and homogenising tasks. Thanks to the intelligent combination of several cutting principles in one machine, the production of superfine products becomes possible in one operation.

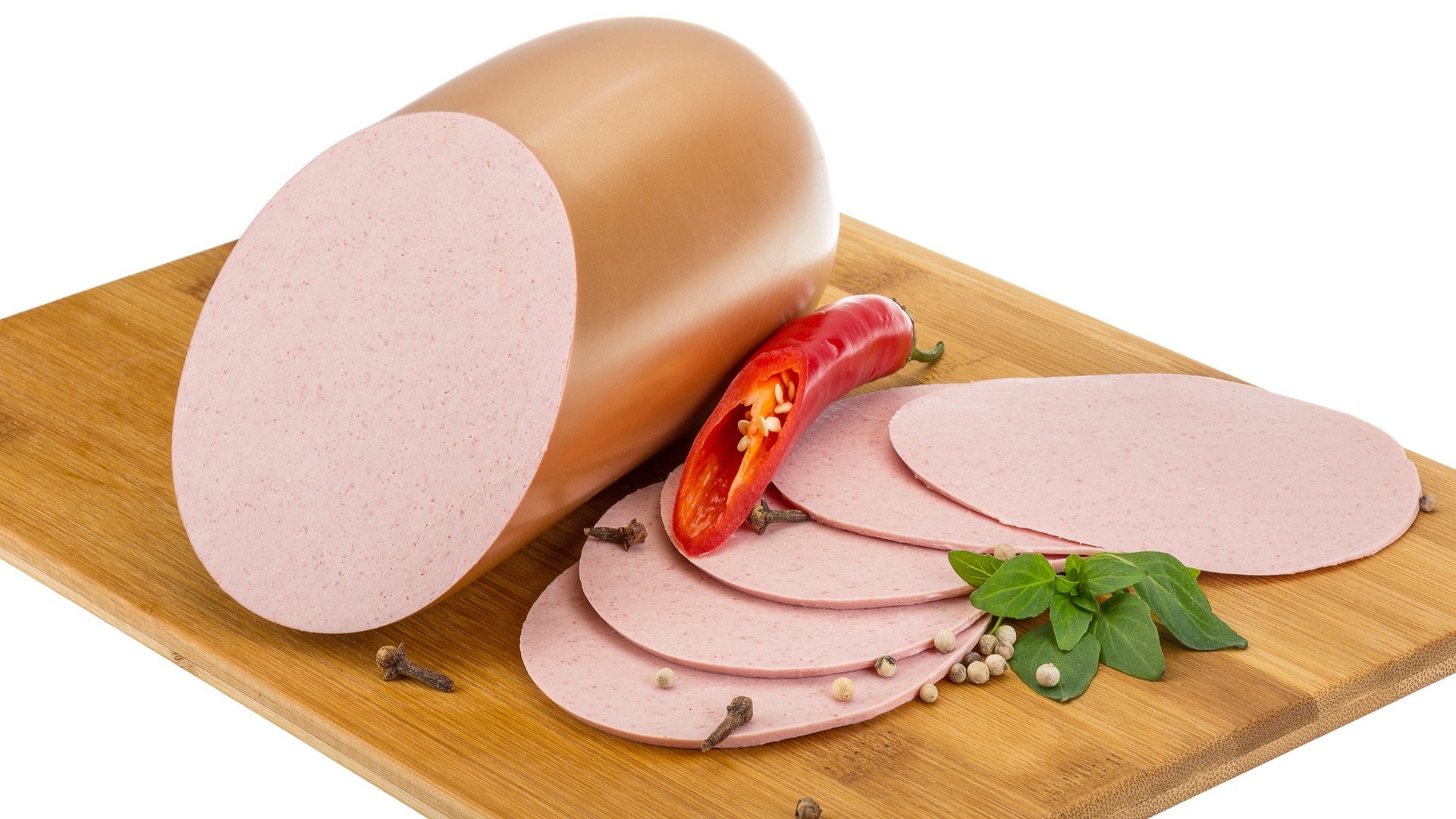

The quality of sausages, vegetarian delicatessen products, pet food as well as baby and pureed food is mainly based on an excellent fine emulsion. Compared to conventional methods, a higher degree of fineness with best consistency is achieved by production with KS equipment.

KARL SCHNELL offers an innovative further development of the traditional emulsifier with its new KS Emulsifiers FL175. Thereby enormous technological advantages result for the customer in the production process.

- The feeding via screw allows a better temperature control even with stiff products.

- The KS cutting system with its manifold cutting set versions enables almost contact-free cutting for exceptional fineness and best consistency with simultaneously lowest wear of the cutting tools.

- The production of fine emulsion from frozen, pre-cut raw material is possible without additional preparation effort.

- KS emulsifiers of the FL-series provide an entry into the process automation for the production of emulsified products and auxiliary materials.

Equipped with the unique KS cutting system, due to the large number of possible combinations optimum results are achieved at all degrees of fineness.

Advantages of the KS Emulsifier FL175 are unparalleled flexibility in various application ranges, at low temperature increase and extremely short emulsification times. In addition, this high-tech machinery is characterised by long service lives at low production costs.