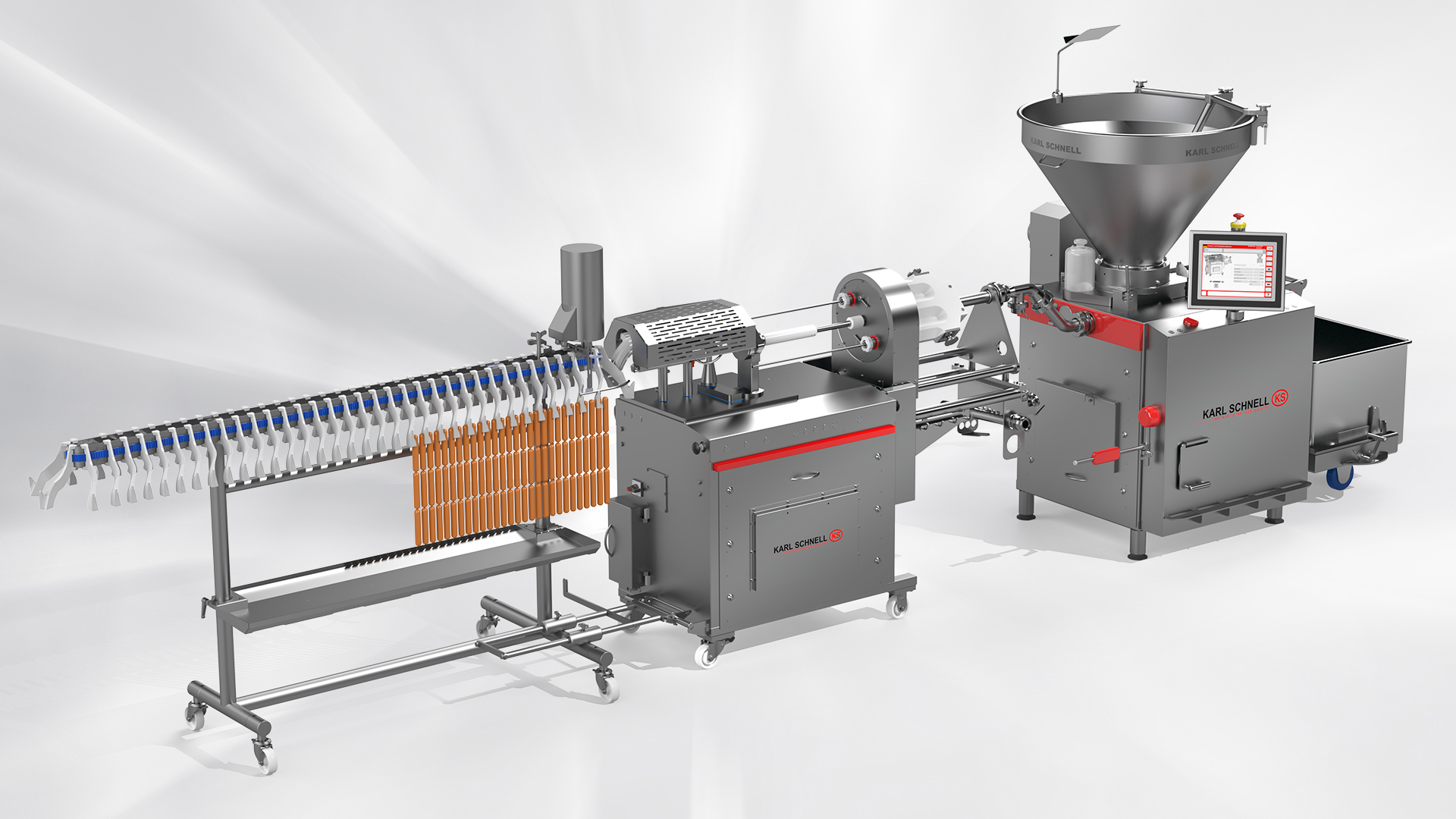

Sausage hanging line

Fully automatic, flexible, efficient!

Sausage hanging line

Fully automatic, flexible, efficient!

Added value by automation

Designed for use in industrial sausage production, the completely new developed

KS Portioning & Hanging Line offers the highest level of reliability and production optimization to the client.

The modular system, consisting of filling machine, portioning and linking device APG with hanging device AHG is operated and controlled via the KS Vacuum Filler. Thus all production parameter can be called up and controlled easily and comfortably.

Thanks to the fully automatic filling process with subsequent fully automatic change of casings a high degree of rationalization at steady optimization of the product quality is achieved.

The KS Portioning & Hanging Line is flexible applicable for all kinds of casings (natural, collagen, cellulose, artificial casings). Therefore, boiled or raw sausages can be produced in a variety of lengths and calibres – always with the highest length and weight accuracy.

Casing end recognition, split casing monitoring, a generously dimensioned casing slug storage and short casing changing times ensure an efficient production at simultaneous optimization of the product quality.

The KS Portioning & Hanging Line provides process reliability, quality and lasting value and thus a value enhancement for the client.