PORTIONing Device P667

The Patty Former!

PORTIONing Device P667

The Patty Former!

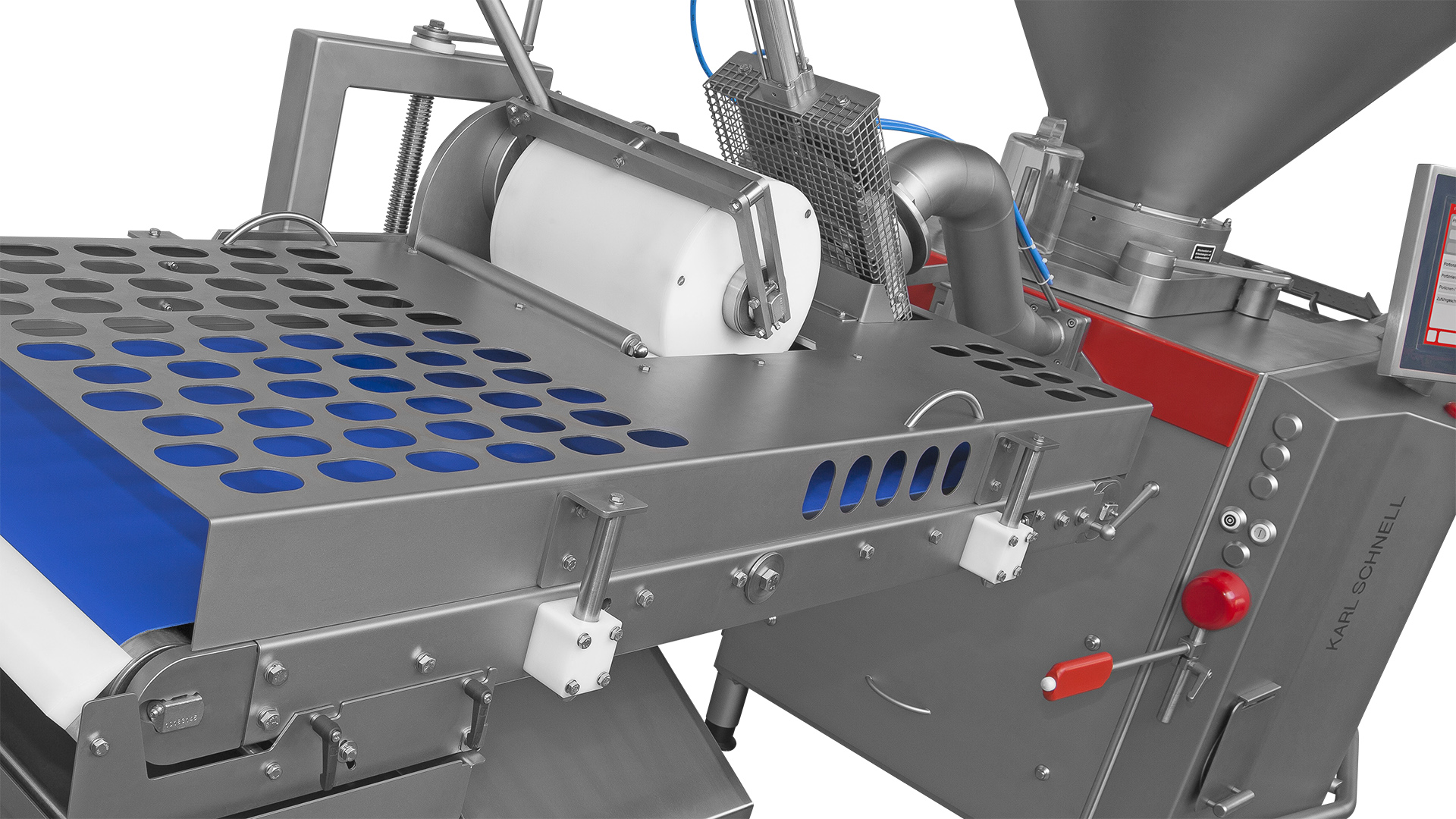

Best forming for the perfect burger patty

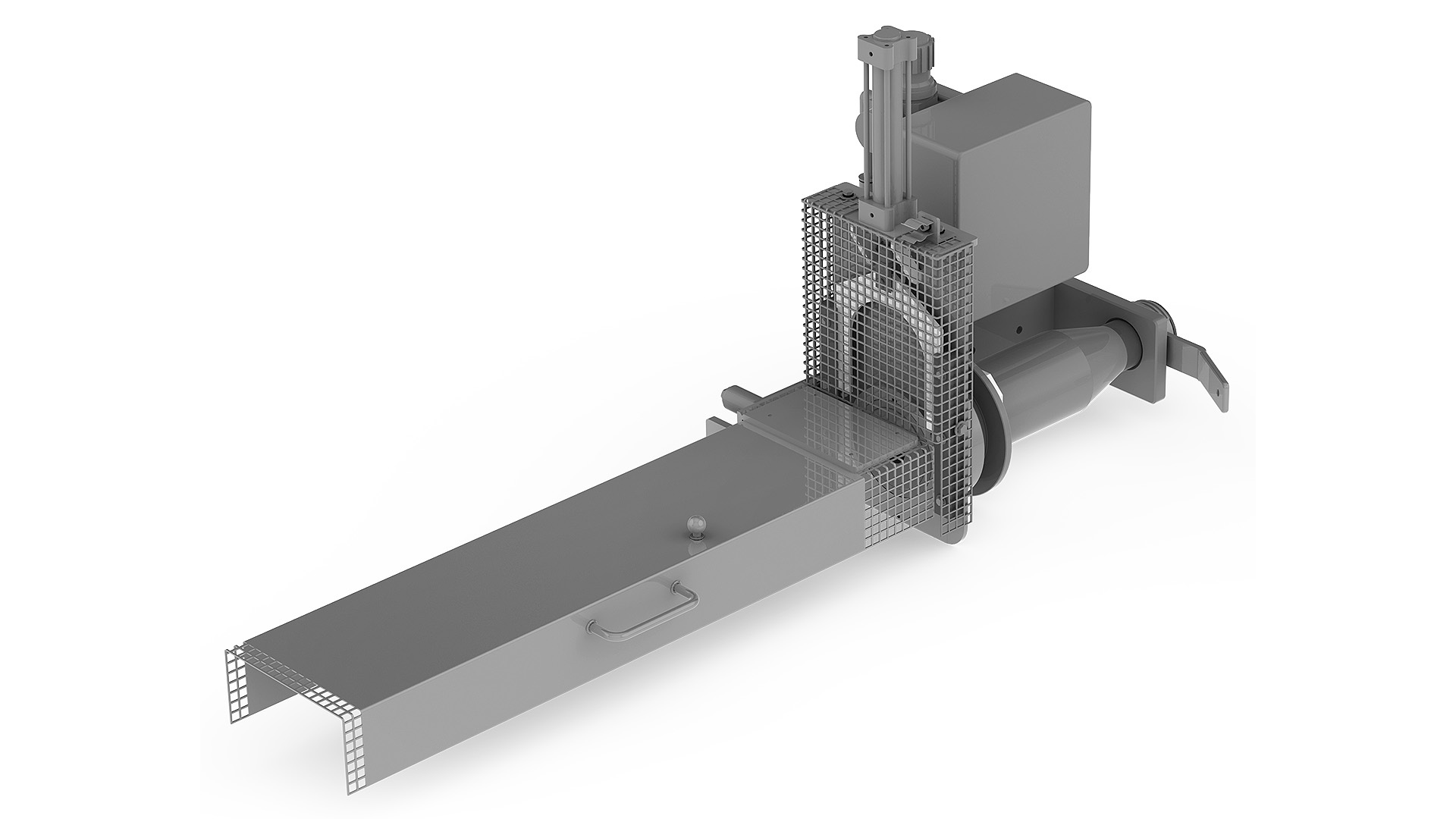

The Patty Former consists of the KS Portioning Device P667 and a conveyor belt with flattening device, directly connected and controlled by the KS Vacuum Filler.

The output pieces are produced by means of the cutting device and then rolled to a predetermined thickness. The speeds of belt and roll are controlled separately. This allows different levels of smoothing and shapes. Thus, malleable masses of round slices can be made to strongly oval shapes.

The desired plate thickness can be easily and repeatedly adjusted via an eccentric.

The cutting device can produce up to 100 parts / min with the highest weight accuracy.