Heating System uht

Continuously successful!

Heating System uht

Continuously successful!

How can product quality, productivity and efficiency in processed cheese production be improved?

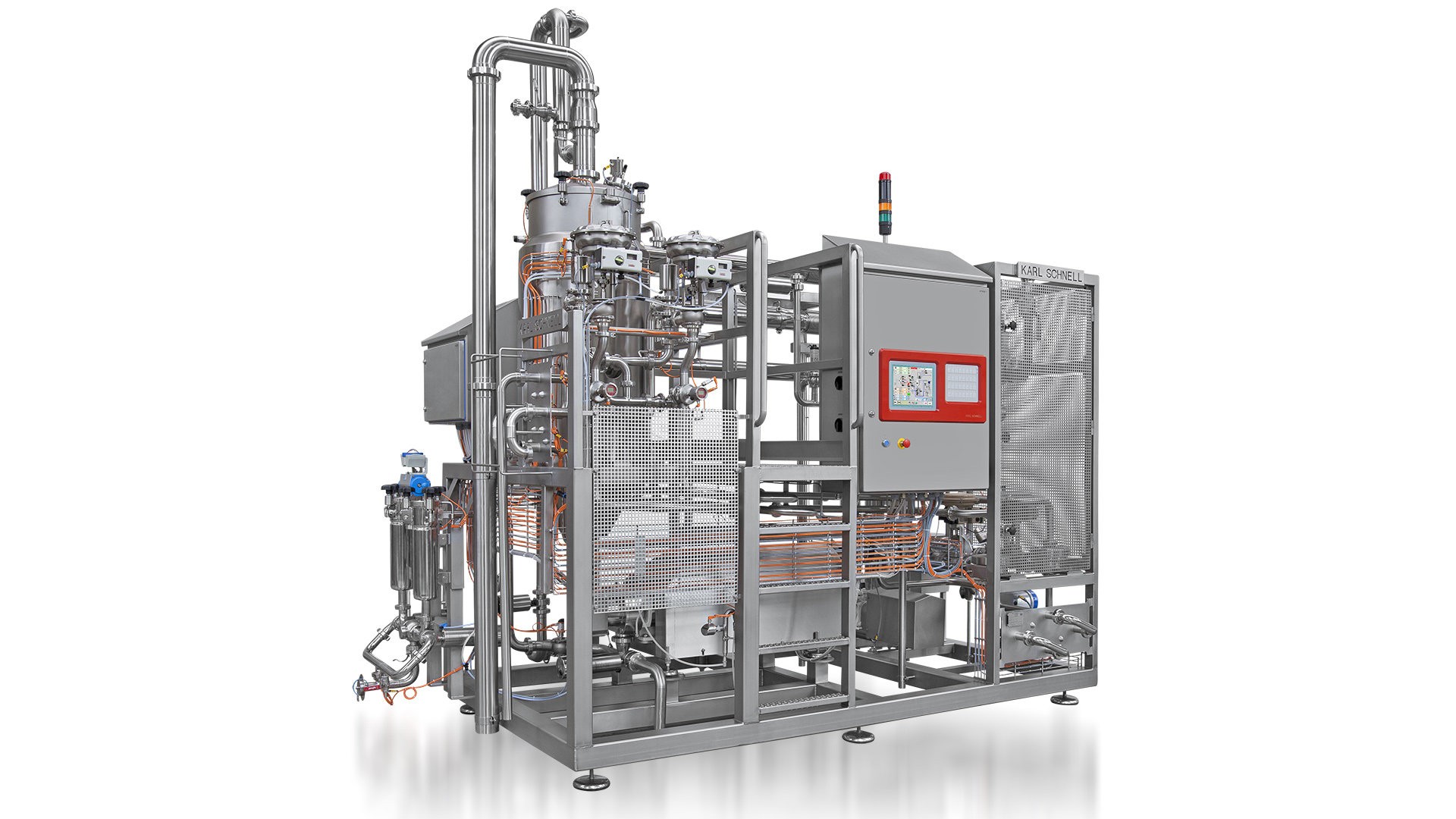

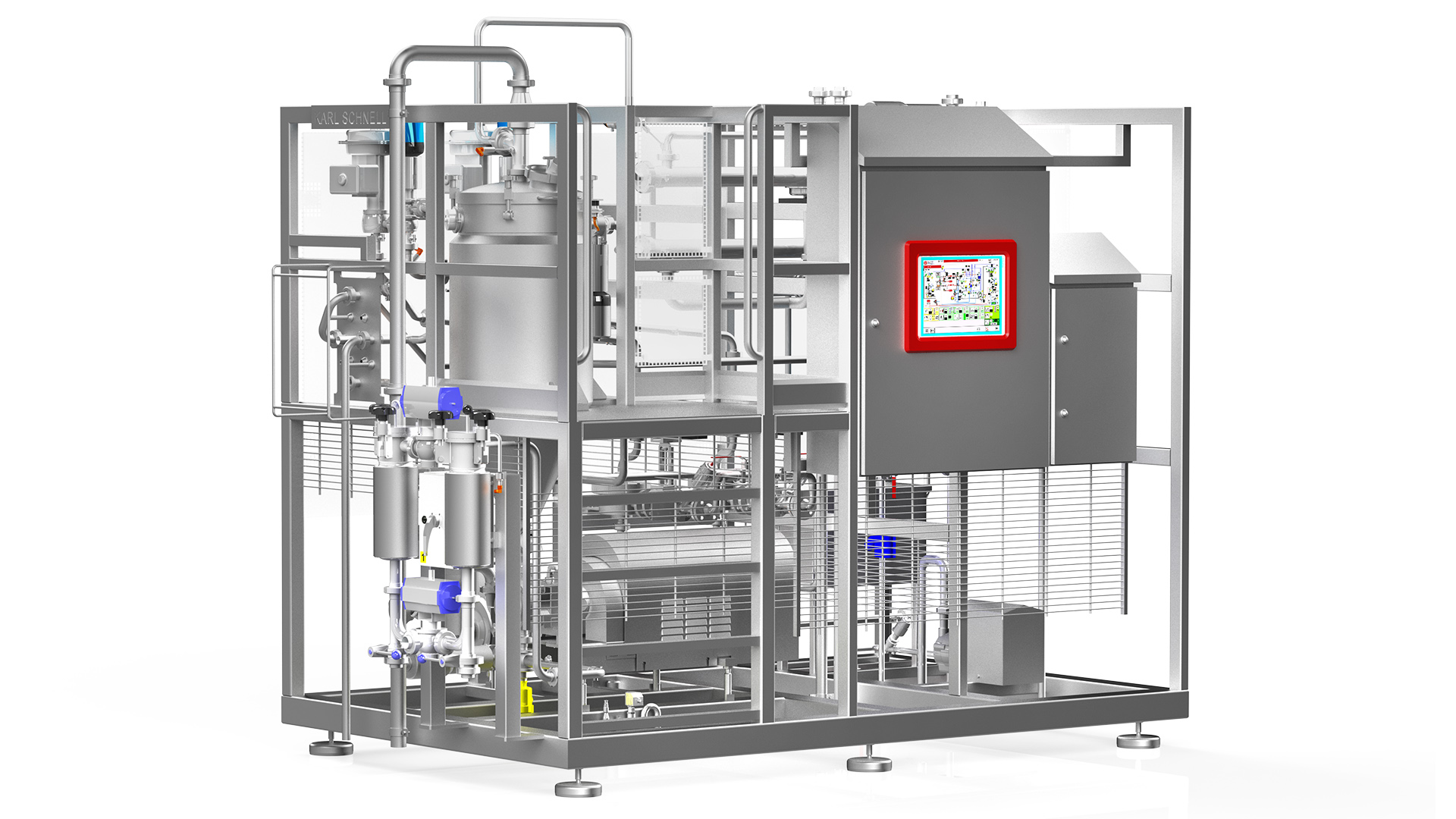

The KS Heating System is a two-stage and continuous operating pasteurisation and sterilisation system. It is developed specifically for prolonging the shelf life of processed cheese, processed cheese preparations and related products.

To produce high-quality goods, reproducible at any time, under energy efficiency aspects in a modern facility, the use of a continuously working heating unit is essential. KARL SCHNELL meets the worldwide complex requirements with the KS Heating System UHT, which is matchless in terms of flexibility, performance and reliability.

The KS Heating System UHT is suitable both for the use in smaller businesses and also for the industrial large-scale production. Variable production capacities from 50-150 l/h (e.g. for research & development) up to 2000 – 6000 l/h for industrial plants are offered. The KS product portfolio meets all customer requirements.

The plant is equipped with two independent heating circuits, which are switchable manually or fully automatically. This offers the operator the flexible organization of his production process. Therefore, higher efficiency and an increase of the quality standard is achieved.

Direct steam injectors – adapted to the respective product – ensure an even and gentle heating. Downstream dynamic, static or so-called high-shear mixers guarantee an optimum mixing of steam and product. Thus, various low to high-viscous processed cheese products with their respective characteristic quality and product features can be processed safely and reproducible.

During production and cleaning all CCP parameters (critical control points) are monitored and automatically readjusted if necessary. These parameters can be written, secured and used as complete quality certification for audits and for the quality assurance.

The KS Heating System UHT is CIP/SIP – designed and built according to the latest international hygienic standards. Cleaning takes place through a integrated CIP equipment or by a customer-provided CIP station. In combination with the highly developed KS control technology optimum cleaning results are ensured.

The process integration of the plant guarantees the trouble-free processed cheese production also with a consistent weekly production in three-shift operation – continuously.